As the experts in precision masking solutions, Caplugs offers the most comprehensive range of standard masking devices and in-house custom capabilities, including the full line of Shercon masking products. Our broad range of parts are designed to securely hold, cover or protect your product during any finishing process, including painting, powder coating, anodizing, plating and e-coating.

Our exceptional team of customer service representatives is standing by to answer your questions and help you find the right part for your needs. Plus, with our global manufacturing facilities and distribution partners around the world, we offer reduced lead times to help deliver the precision masking devices you need on time, every time.

Caplugs now offers a wide range of bore masking solutions to protect highly precisioned machined surfaces during painting and blasting processes. Find masking made for heavy machine manufacturing.

Bore Mask Series

Shop more than 13,000 masking parts – including the full Shercon masking line – in our catalog.

Download Catalog

Caplugs offers an extensive catalog of masking parts, tapes and die-cuts. In addition to our in-stock and ready-to-ship catalog solutions, we are experts in developing custom masking solutions. Learn more about how we can help improve the speed and quality of your finishing work or help save on labor and materials with our catalog and custom masking parts.

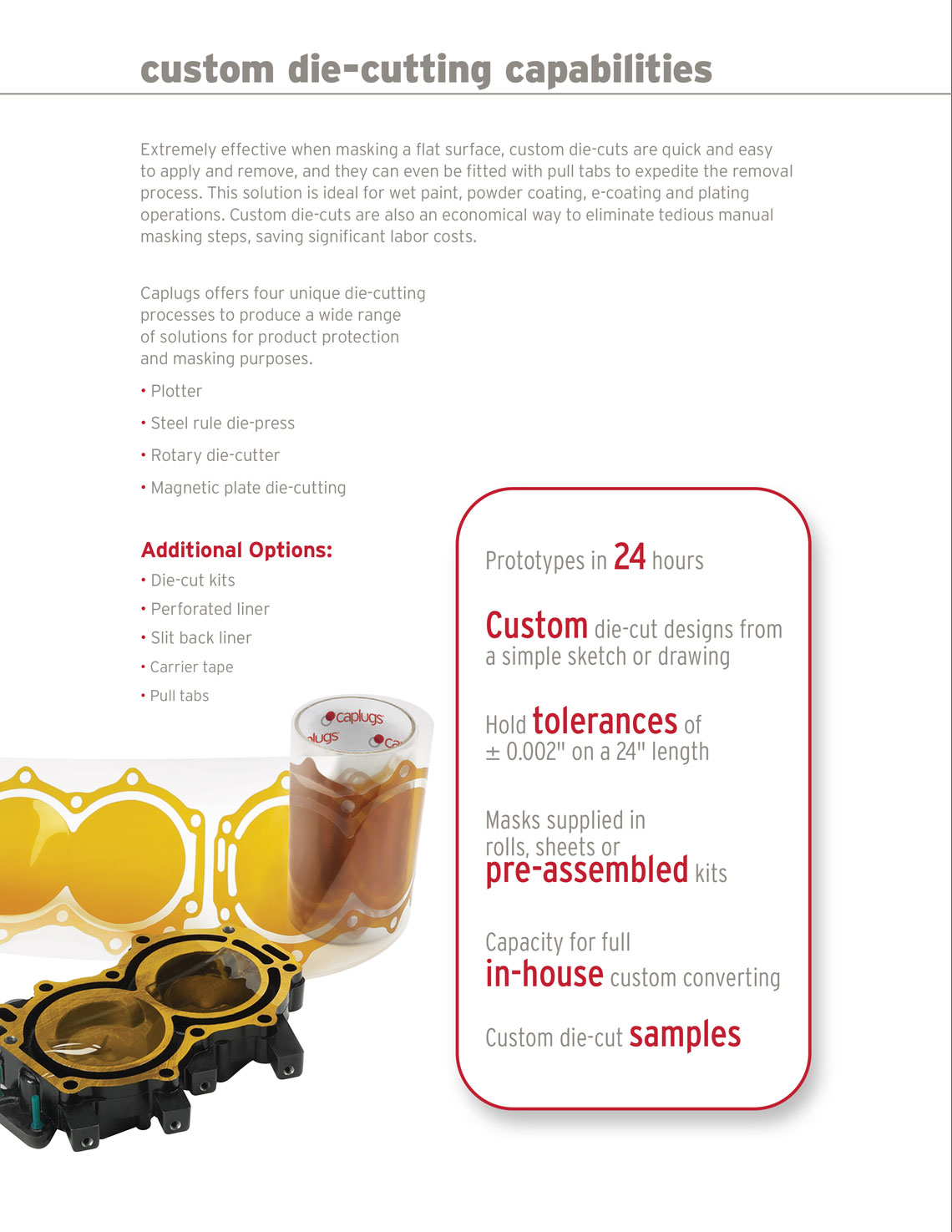

Caplugs’ die-cutting process is done in house, allowing for full customization, quicker turnarounds and more affordable pricing. We offer die-cutting for standard and custom materials – including adhesive backing – and can handle sizes up to 60 inches by 120 inches.

Die-Cuts & DiscsCustomers can choose from four processes – sample plotter, rotary die cutter, steel rule die machine or flash cutter – and we can handle both simple designs and complex geometries. Shop our full line of standard die-cuts now or learn more about custom capabilities.

Custom Capabilities

Caplugs offers masking solutions for every industry. As the manufacturer of Shercon precision masking caps and plugs, you’ll find protection for studs, tube ends, slotted holes and more to keep your products protected through any finishing process.

Choose from cap and plug designs that offer a range of features while being easy to install and remove. Versatile options such as vented designs, hollow core or dual-purpose plugs offer flexibility to suit your specific masking application. We also offer parts in UltraBake™ silicone or Flex500® to withstand extreme temperatures.

We also offer an extensive range of masking tapes, discs and die-cuts that quickly apply and remove, leaving no adhesive residue behind. Choose from a range of materials to withstand abrasion, chemical solvent baths or extreme temperatures in your finishing operations. We also offer a range of color options, including our new clear masking line, and features like pull-tabs to make masking faster and easier. Explore our full line of masking and find the right solution today.

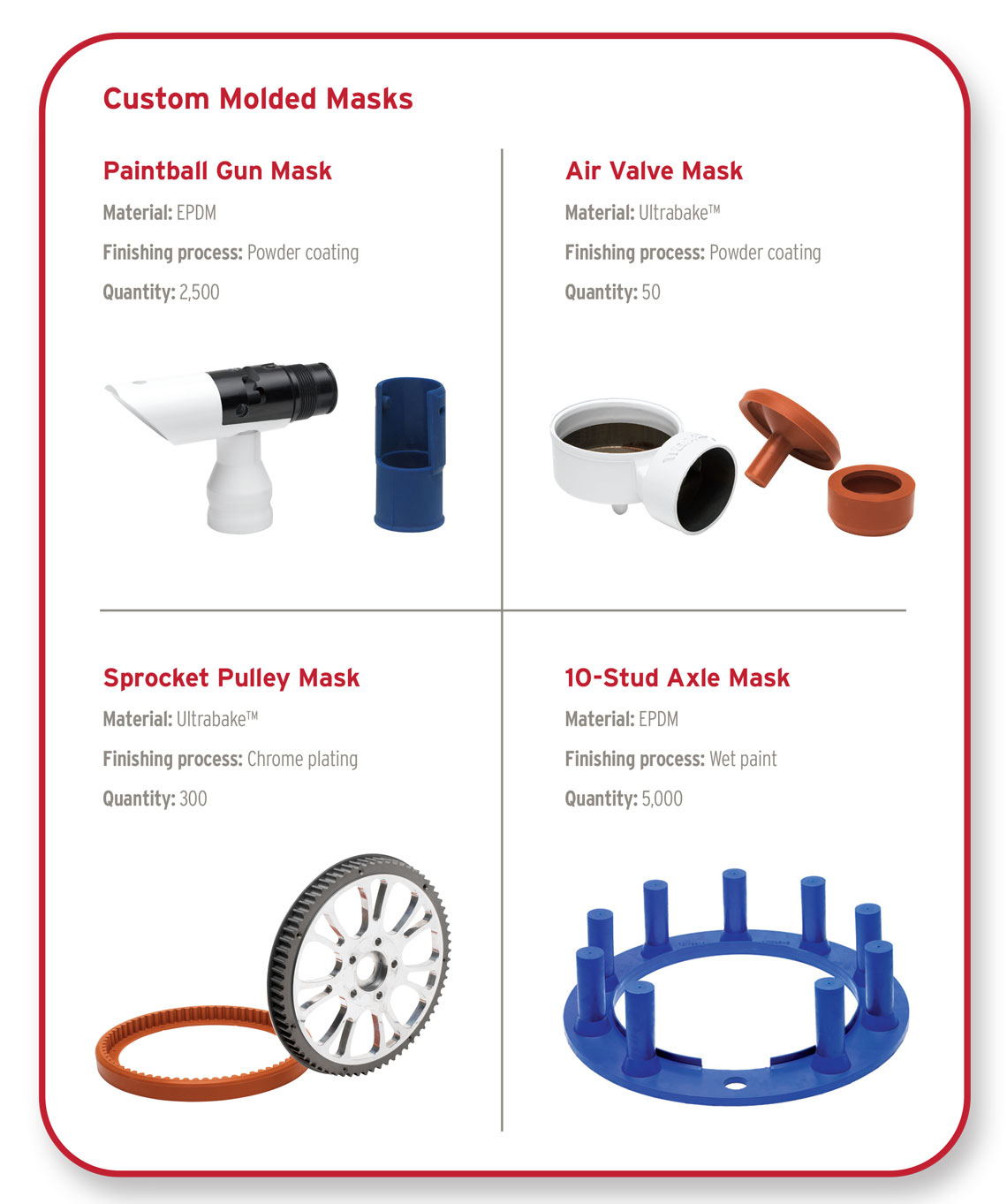

When one of our standard masking devices doesn’t meet your needs, our design engineers will work one-on-one with you to develop a custom solution tailored for your application. Our experienced team of engineers will create an innovative, cost-effective masking device to solve any problem. They can walk you through every step of the process by identifying your needs, creating prototypes and developing the final product.

Custom masking can help improve your productivity and speed production lines, enhance the quality and consistency of your finishing operations and avoid expensive masking failures and reworking, helping drive down your overall cost of production. Curious how much custom masking could save you? Take three minutes to try our custom masking calculator and learn how much time and money a made-to-fit part could save you.

Our custom process allows us to develop unique masking solutions more quickly and economically than anyone in the industry.

As a global leader, we have the facilities, molding capabilities, engineering resources, quality certifications and processes to meet your needs. Our world-class sales and service team will work alongside you at every step in the process to develop custom parts that fit your exact requirements.

A dedicated sales engineer works with you one-on-one to fully identify and understand your challenges – the application for your component, the environmental factors and challenges in the process. Our engineers will then develop a prototype to review and confirm the fit before moving to manufacturing and delivery. From concept and design to tooling and full volume production, we work as your partner in product protection, and offer the worldwide capabilities to deliver the parts you need on time and on budget quickly – no matter where you are or what you need.